About Us – SHREE GANESH TECHRUB INDUSTRIES

“To be a trusted global leader in rubber ring and molded component manufacturing, proudly rooted in India, delivering innovative, reliable, and sustainable sealing solutions that empower industries worldwide.”

About

Vision of SHREE GANESH TECHRUB INDUSTRIES:

Established on 1st September 2020, SHREE GANESH TECHRUB INDUSTRIES is now a trusted name to reckon in the manufacturing of precision-engineered rubber rings and moulded components. Experienced with 5 years, the company continues to rise further under the visionary leadership of Mr. Prateek Agarwal, our motivation and founder.

keyperson :- Krishna Kant todi

The commitment of Mr. Agarwal towards innovation, quality, and sustainability gives strength to our operations.

Head Office & Manufacturing Unit:

SHREE GANESH TECHRUB INDUSTRIES

B-11, Old Industrial Estate, Bhilwara – 311001, Rajasthan, India

We supply our products across Mumbai, Ahmedabad, Udaipur, Jaipur, Delhi, Jalgaon, and extend our wings across Maharashtra, Gujarat, and India.

Our purpose is a statement of this commitment:

- To be the most sought-after collaborator for the highest quality rubber products

- To produce precision rubber rings and moulded components by the latest compression moulding

- To serve industrial industries with cost-effective, long-lasting, and customised sealing solutions

- To actively contribute to the ‘Make in India’ initiative through innovation and quality

- To ensure client satisfaction with timely delivery, transparency, and dedicated support

- To foster a work culture focused on continuous improvement, employee growth, and eco-conscious production

Our Manufacturing Process

Our Customers

What We Provide

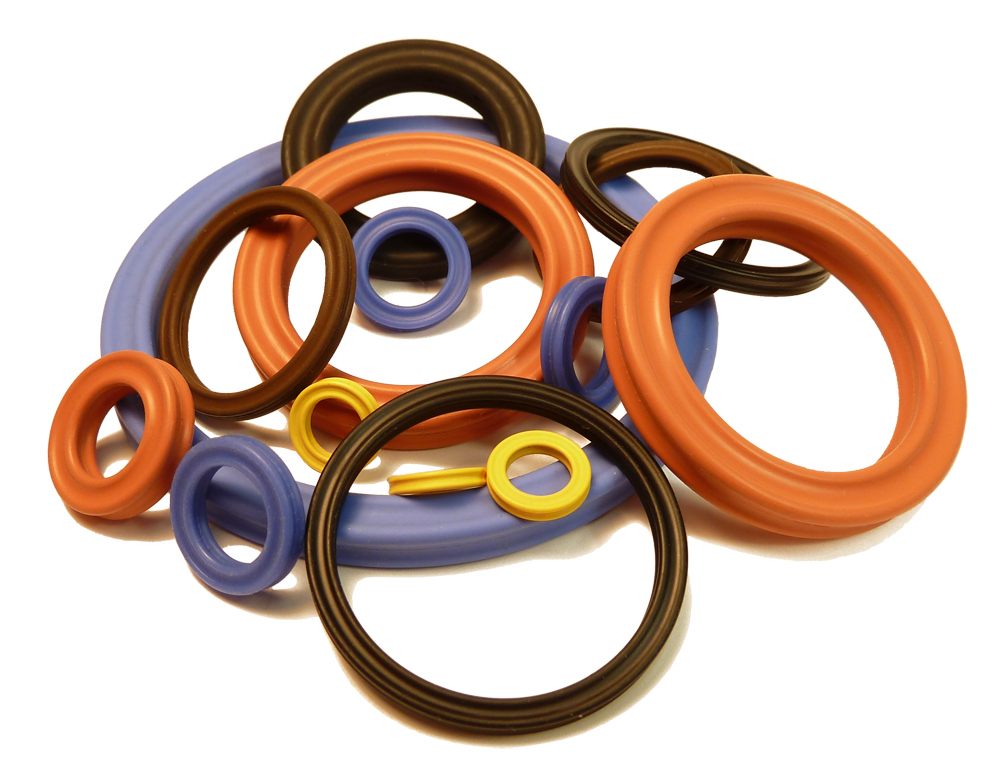

SHREE GANESH TECHRUB INDUSTRIES is a well-known expert in manufacturing high-quality rubber O-rings and molded rubber goods that are specifically manufactured to meet the needs of industrial applications.

- Rubber O-Rings for Pipe Systems

- We provide sealing solutions for:

- DWC Pipes (Double Wall Corrugated Pipes):

- O-rings as specially engineered leak-proof seals for underground drainage and cable

duct protection systems. - AC Pressure Pipes (Asbestos Cement Pipes):

- Strength and ductility in variable field conditions of leak-tolerant O-rings.

- Heavy-duty rubber rings for long drinking water pipes, sewage, and industrial applications.

- SWR Pipes (Soil, Waste & Rainwater Pipes):

- Chemically resistant O-rings are ideal for non-pressure sewerage and drainage systems.

- Sprinkler Pipes / Irrigation Systems:

- O-rings for close fits in industrial and farm sprinkler pipes.

Our rings are manufactured using top-grade materials such as EPDM, Nitrile, Neoprene, Silicone, NR, SBR, and Viton, which give them enhanced chemical resistance, elasticity, and dimensional stability.

Custom Rubber Molded Products

We also trade in custom rubber molding products apart from our inventory of O-rings. If you need a special design, material grade, or quantity purchase, we offer full-fledged custom

solutions:

- Production through drawings or customer-supplied samples

- In-house speciality mold design for special shapes

- Compression molding technology for high accuracy and repetitive manufacturing

- Material selection to be adaptable based on the application of use

- High volume bulk production with cost savings

- These specialised products address the requirements of diverse industries like:

- Water Supply & Drainage

- Agriculture & Irrigation

- Electrical & Cable Industries

Let's Connect

Whether you require long-lasting pipe sealing solutions or in-house-designed rubber

components, SHREE GANESH TECHRUB INDUSTRIES is your single point of contact.

Through experience, technical inputs, and a customer-focused approach, we’re committed to

delivering high-quality products that deliver and last.

FAQ's

Q1: What kind of rubber compounds do you employ in your O-rings?

A: We employ a wide range of materials, including EPDM, Nitrile (NBR), Neoprene, Silicone,

SBR, NR, and Viton,

Q2: Can I order a non-standard rubber product to our specifications?

A: Yes, we also offer custom rubber molding where we are able to manufacture from your

drawing or sample. We do make molds as well as help with selecting the material.

Q3: Do you deliver pan-India?

A: Yes, we have a presence in India with regular shipments to Mumbai, Delhi, Gujarat,

Rajasthan, and Maharashtra.

Q4: What sectors do you supply to?

A: We supply our products for water supply, wastewater treatment, agriculture, construction, automotive, and electrical sectors.

Q5: What is your order size?

A: We deal in medium and large-sized orders, competitive rates, and guaranteed supply schedules.

Q6: How do you ensure product quality?

A: We do strict dimension inspections, chemical inspections, and physical inspections of all products. We also follow standardised production procedures and utilise state-of-the-art compression molding machines.